|

|

PDF CLA200 Data sheet ( Hoja de datos )

| Número de pieza | CLA200 | |

| Descripción | CMOS Gate Arrays | |

| Fabricantes | Zarlink Semiconductor | |

| Logotipo | ||

Hay una vista previa y un enlace de descarga de CLA200 (archivo pdf) en la parte inferior de esta página. Total 11 Páginas | ||

|

No Preview Available !

( DataSheet : www.DataSheet4U.com )

CLA200 Series

CMOS Gate Arrays

Advance Information

INTRODUCTION

The CLA200 Series Arrays from Zarlink Semiconductor offer

designers the capability to integrate designs of more than 2

million gates. There are 14 fixed arrays optimised for low to

medium complexity designs ranging from 11K used gates up

to 628K used gates. For larger designs optimised arrays can

be built with up to 3 million available gates. Using automated

gate array base constructor software, a tailor made optimised

gate array can be built to customers requirements which gives

designers the ability to specify the optimum die size whilst

retaining the benefits of standard gate arrays. Utilising a gate

array architecture allows the base arrays to be pre-

manufactured enabling gate array prototype lead time to be

offered.

Supported with high quality design kits for a range of industry

standard CAE tools, the CLA200 Series provide customers

with a low risk, low cost solution and fast time to market.

FEATURES

• 0.35µm drawn Channel Length

• Three (CLT) and Four (CLQ) layer metal options

• Automated base array constructor for optimised arrays

with up to 3 million gates

• Low Power, 0.4µW/MHz/Gate at 3V (2-input NAND with

two loads)

• 135ps gate delay for 2-input NAND with two loads (3V)

• High density staggered pad ring

• Wide range of package options including QFP & BGA

• Characterised for operation from 1.8V to 3.6V

• 2V and 3.3V I/O capability on the same device

• 5V tolerant inputs, outputs and bidirectionals

• Accurate delay modelling for gates and tracks with sign

off quality CAE design libraries for QuickSim II and

Verilog-XL

• VITAL Sign off with Synopsys VSS Simulator

• CAD libraries optimised for synthesis

• Methodologies for low clock skew

• Full set of I/O cells for direct pad synthesis

• Variable output slew rates for low noise

• IDDQ Testing

BENEFITS

• Fast Customer Time To Market

- Direct sign-off on Industry Standard CAE tools

- Comprehensive Industry Standard CAE tools

- SystemBuilder™ megacell libraries

- World-wide design center support

- Reliable prototype and production delivery

- Dual silicon sources

DS4812

ISSUE 1.3

July 1997

• Cost -effective solutions

- Optimised silicon architecture for high density silicon

utilisation

- ISO9001 Factory with Statistical process control for

optimum yield

FIXED ARRAY SIZES

Available Available

Pads

Gates

CLA201

CLA202

CLA203

CLA204

CLA205

CLA206

CLA207

CLA208

CLA209

CLA210

CLA211

CLA212

CLA213

CLA214

48

64

80

100

128

144

160

176

208

240

272

304

328

352

17,860

30,012

45,300

68,736

109,980

137,812

168,780

202,884

280,500

370,660

473,364

588,612

683,280

785,004

Usable

Gates

TLM

10,700

18,000

27,200

41,200

66,000

82,700

101,300

121,700

168,300

222,400

284,000

353,200

410,000

471,000

Usable

Gates

QLM

14,300

24,000

36,200

55,000

88,000

110,200

135,000

162,300

224,400

296,500

378,700

470,900

546,600

628,000

OPTIMISED ARRAYS

The following table illustrates examples of possible compiled

array sizes.

Available Available

Pads

Gates

Usable

Gates

TLM

Usable

Gates

QLM

CLA2xx

400

989,740 590,000

790,000

CLA2xx

552

1,879,776 1,100,000 1,500,000

CLA2xx

700

3,018,424 1,800,000 2,400,000

www.DataSheet4U.com

www.DataSheet4U.com

1 page

Stage 1

Stage 2

Stage 3

Figure.1

Advance Information CLA200 Series

Advanced Delay Modelling

Delay calculation includes the following features:

• Edge speed modelling

• Pin to pin timings

• Non-linear delay modelling

• Accurate delay derating

• Conditional delay modelling

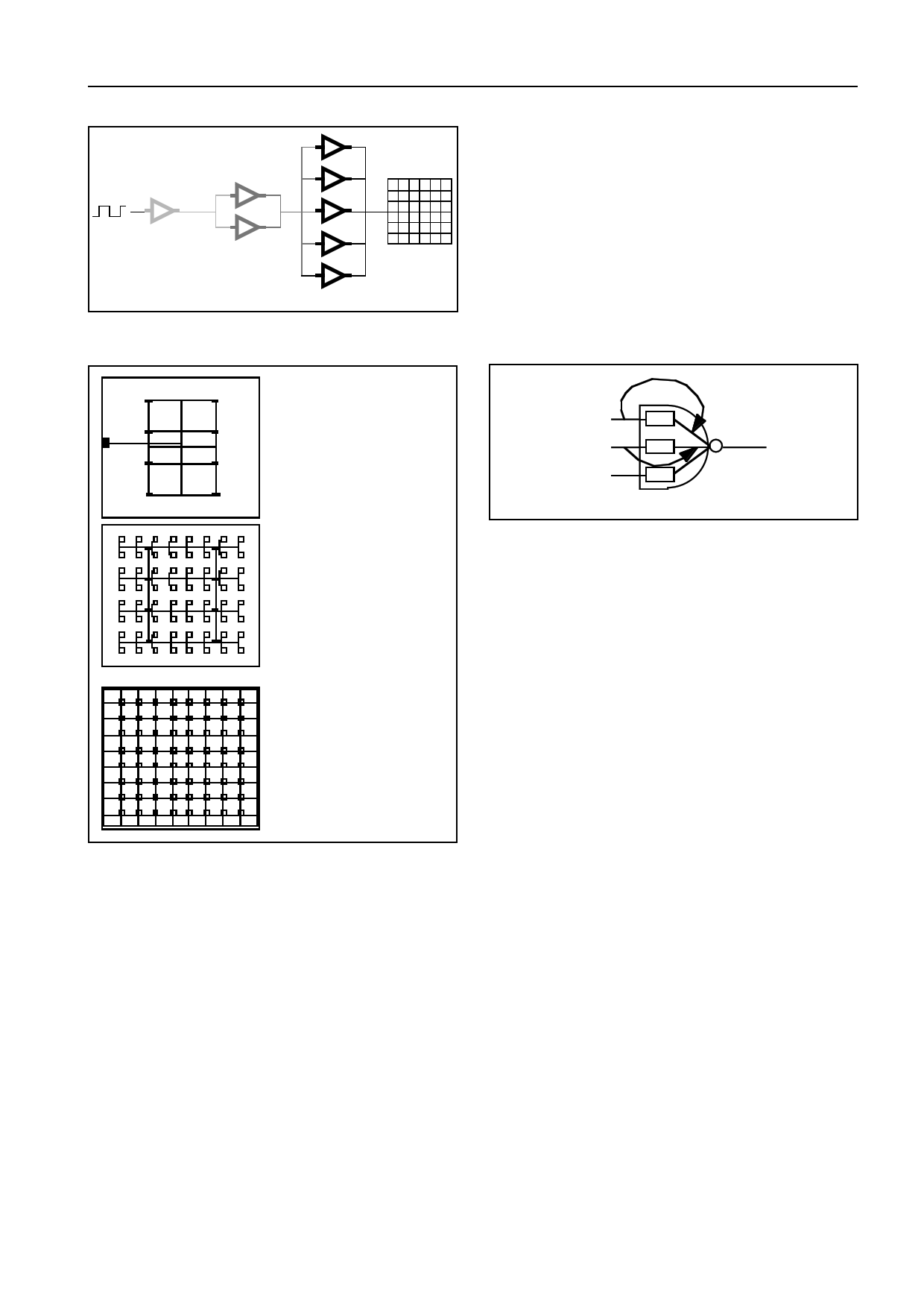

Pin to Pin Delays

Delay models use times between individual input and output

pins for both rising and falling delays, as illustrated in figure 3

below.

Stage 1 output grid

Stage 2 output grid

Stage 3 output grid

Figure.2

A

BF

C

Figure.3

Calculation uses individual pin to pin delays, e.g. A to F and B

to F, which improves simulation accuracy by modelling the

considerable variation in delay between different input pins.

For complex gates (e.g. AND-NOR gates or adders) the

variation is up to 40%. For simple NAND and NOR logic gates

the typical variation is 20%.

Non-linear Curve Fitting

For fast input edges (0.5ns) delay time increases linearly with

the output load, whereas for high output loads delay increases

linearly with edge speed. Delays for slow input edges and light

input loads do not follow the linear model, so a simple linear

model cannot represent delays accurately. A more complex

equation, which includes interaction between edge and load

factors, is used to model delays.

Thermal Management

The increase in speed and density available through

advanced CMOS processes results in a corresponding

increase in power dissipation. Designs can now have more

than half a million used gates and chip power consumption is

an important issue.

The CLA200 series offers the following:

• Lower power CMOS for improved thermal management

• Software constructed power grids for efficient power

distribution

• Copper lead frame QFPs for lower thermal resistance

• High pinout power packages available

5

5 Page

http://www.zarlink.com

World Headquarters - Canada

Tel: +1 (613) 592 0200

Fax: +1 (613) 592 1010

North America - West Coast

Tel: (858) 675-3400

Fax: (858) 675-3450

North America - East Coast

Tel: (978) 322-4800

Fax: (978) 322-4888

Asia/Pacific

Tel: +65 333 6193

Fax: +65 333 6192

Europe, Middle East,

and Africa (EMEA)

Tel: +44 (0) 1793 518528

Fax: +44 (0) 1793 518581

Information relating to products and services furnished herein by Zarlink Semiconductor Inc. trading as Zarlink Semiconductor or its subsidiaries (collectively “Zarlink”) is

believed to be reliable. However, Zarlink assumes no liability for errors that may appear in this publication, or for liability otherwise arising from the application or use of any

such information, product or service or for any infringement of patents or other intellectual property rights owned by third parties which may result from such application or

use. Neither the supply of such information or purchase of product or service conveys any license, either express or implied, under patents or other intellectual property rights

owned by Zarlink or licensed from third parties by Zarlink, whatsoever. Purchasers of products are also hereby notified that the use of product in certain ways or in

combination with Zarlink, or non-Zarlink furnished goods or services may infringe patents or other intellectual property rights owned by Zarlink.

This publication is issued to provide information only and (unless agreed by Zarlink in writing) may not be used, applied or reproduced for any purpose nor form part of any

order or contract nor to be regarded as a representation relating to the products or services concerned. The products, their specifications, services and other information

appearing in this publication are subject to change by Zarlink without notice. No warranty or guarantee express or implied is made regarding the capability, performance or

suitability of any product or service. Information concerning possible methods of use is provided as a guide only and does not constitute any guarantee that such methods of

use will be satisfactory in a specific piece of equipment. It is the user’s responsibility to fully determine the performance and suitability of any equipment using such

information and to ensure that any publication or data used is up to date and has not been superseded. Manufacturing does not necessarily include testing of all functions or

parameters. These products are not suitable for use in any medical products whose failure to perform may result in significant injury or death to the user. All products and

materials are sold and services provided subject to Zarlink Semiconductor’s conditions of sale which are available on request.

Purchase of Zarlink’s I2C components conveys a licence under the Philips I2C Patent rights to use these components in an I2C System, provided that the system conforms

to the I2C Standard Specification as defined by Philips

Zarlink and the Zarlink Semiconductor logo are trademarks of Zarlink Semiconductor Inc.

Copyright 2001, Zarlink Semiconductor Inc. All rights reserved.

TECHNICAL DOCUMENTATION - NOT FOR RESALE

11 Page | ||

| Páginas | Total 11 Páginas | |

| PDF Descargar | [ Datasheet CLA200.PDF ] | |

Hoja de datos destacado

| Número de pieza | Descripción | Fabricantes |

| CLA200 | CMOS Gate Arrays | Zarlink Semiconductor |

| Número de pieza | Descripción | Fabricantes |

| SLA6805M | High Voltage 3 phase Motor Driver IC. |

Sanken |

| SDC1742 | 12- and 14-Bit Hybrid Synchro / Resolver-to-Digital Converters. |

Analog Devices |

|

DataSheet.es es una pagina web que funciona como un repositorio de manuales o hoja de datos de muchos de los productos más populares, |

| DataSheet.es | 2020 | Privacy Policy | Contacto | Buscar |