|

|

PDF NCP1608BDR2G Data sheet ( Hoja de datos )

| Número de pieza | NCP1608BDR2G | |

| Descripción | Critical Conduction Mode PFC Controller Utilizing a Transconductance Error Amplifier | |

| Fabricantes | ON Semiconductor | |

| Logotipo | ||

Hay una vista previa y un enlace de descarga de NCP1608BDR2G (archivo pdf) en la parte inferior de esta página. Total 24 Páginas | ||

|

No Preview Available !

NCP1608

Critical Conduction Mode

PFC Controller Utilizing a

Transconductance Error

Amplifier

The NCP1608 is an active power factor correction (PFC)

controller specifically designed for use as a pre−converter in ac−dc

adapters, electronic ballasts, and other medium power off−line

converters (typically up to 350 W). It uses critical conduction mode

(CrM) to ensure near unity power factor across a wide range of input

voltages and output power. The NCP1608 minimizes the number of

external components by integrating safety features, making it an

excellent choice for designing robust PFC stages. It is available in

a SOIC−8 package.

General Features

• Near Unity Power Factor

• No Input Voltage Sensing Requirement

• Latching PWM for Cycle−by−Cycle On Time Control (Voltage

Mode)

• Wide Control Range for High Power Application (>150 W) Noise

Immunity

• Transconductance Error Amplifier

• High Precision Voltage Reference (±1.6% Over the Temperature

Range)

• Very Low Startup Current Consumption (≤ 35 mA)

• Low Typical Operating Current Consumption (2.1 mA)

• Source 500 mA/Sink 800 mA Totem Pole Gate Driver

• Undervoltage Lockout with Hysteresis

• Pin−to−Pin Compatible with Industry Standards

• This is a Pb−Free and Halide−Free Device

Safety Features

• Overvoltage Protection

• Undervoltage Protection

• Open/Floating Feedback Loop Protection

• Overcurrent Protection

• Accurate and Programmable On Time Limitation

Typical Applications

• Solid State Lighting

• Electronic Light Ballast

• AC Adapters, TVs, Monitors

• All Off−Line Appliances Requiring Power Factor Correction

www.onsemi.com

8

1

SOIC−8

D SUFFIX

CASE 751

MARKING DIAGRAM

8

1608B

ALYW

G

1

A = Assembly Location

L = Wafer Lot

Y = Year

W = Work Week

G = Pb−Free Package

PIN CONNECTION

FB

Control

Ct

CS

(Top View)

VCC

DRV

GND

ZCD

ORDERING INFORMATION

Device

Package

Shipping†

NCP1608BDR2G SOIC−8 2500 / Tape & Reel

(Pb−Free)

†For information on tape and reel specifications,

including part orientation and tape sizes, please

refer to our Tape and Reel Packaging Specifications

Brochure, BRD8011/D.

© Semiconductor Components Industries, LLC, 2015

July, 2015 − Rev. 5

1

Publication Order Number:

NCP1608/D

1 page

NCP1608

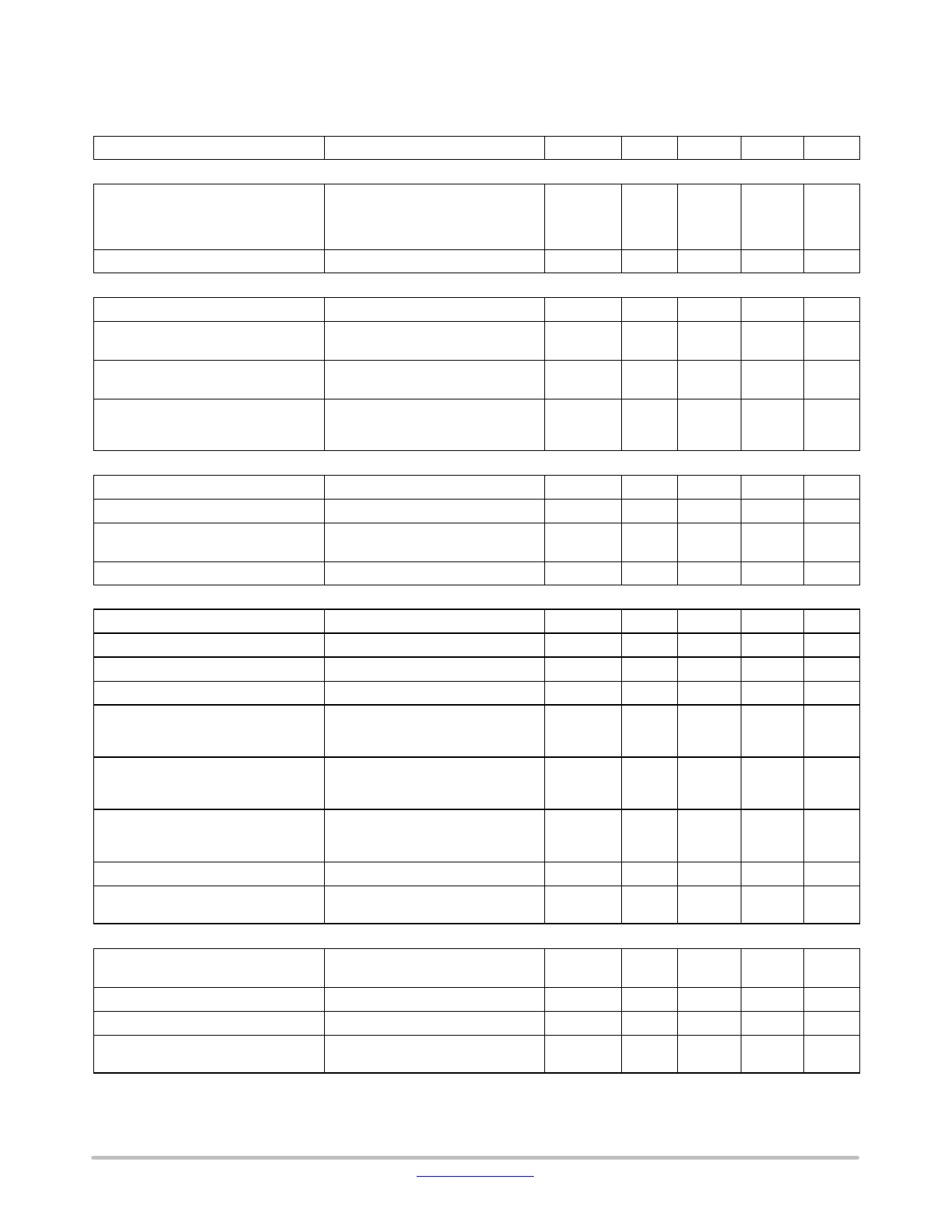

Table 3. ELECTRICAL CHARACTERISTICS (Continued)

VFB = 2.4 V, VControl = 4 V, Ct = 1 nF, VCS = 0 V, VZCD = 0 V, CDRV = 1 nF, VCC = 12 V, unless otherwise specified

(For typical values, TJ = 25°C. For min/max values, TJ = −55°C to 125°C (Note 6), VCC = 12 V, unless otherwise specified)

Characteristic

Test Conditions

Symbol

Min

Typ

Max

Unit

ERROR AMPLIFIER

Minimum Control Voltage to Generate

Drive Pulses

Control Voltage Range

RAMP CONTROL

VControl = Decreasing until

VDRV is low, VCt = 0 V

TJ = −40°C to +125°C

TJ = −55°C to +125°C (Note 6)

VEAH – Ct(offset)

Ct(offset)

VEA(DIFF)

0.37

0.37

4.5

0.65

0.65

4.9

0.88

1.1

5.3

V

V

Ct Peak Voltage

On Time Capacitor Charge Current

VControl = open

VControl = open

VCt = 0 V to VCt(MAX)

VCt(MAX)

Icharge

4.775

235

4.93

275

5.025

297

V

mA

Ct Capacitor Discharge Duration

PWM Propagation Delay

CURRENT SENSE

VControl = open

VCt = VCt(MAX) −100 mV to 500 mV

dV/dt = 30 V/ms

VCt = VControl − Ct(offset)

to VDRV = 10%

tCt(discharge)

tPWM

−

−

50 150 ns

130 220 ns

Current Sense Voltage Threshold

Leading Edge Blanking Duration

Overcurrent Detection Propagation De-

lay

Current Sense Bias Current

ZERO CURRENT DETECTION

VCS = 2 V, VDRV = 90% to 10%

dV/dt = 10 V/ms

VCS = VILIM to VDRV = 10%

VCS = 2 V

VILIM

tLEB

tCS

ICS

0.45 0.5

100 190

40 100

−1 −

0.55

350

170

1

V

ns

ns

mA

ZCD Arming Threshold

ZCD Triggering Threshold

ZCD Hysteresis

ZCD Bias Current

Positive Clamp Voltage

Negative Clamp Voltage

ZCD Propagation Delay

Minimum ZCD Pulse Width

Maximum Off Time in Absence of ZCD

Transition

VZCD = Increasing

VZCD = Decreasing

VZCD = 5 V

IZCD = 3 mA

TJ = −40°C to +125°C

TJ = −55°C to +125°C (Note 6)

IZCD = −2 mA

TJ = −40°C to +125°C

TJ = −55°C to +125°C (Note 6)

VZCD = 2 V to 0 V ramp,

dV/dt = 20 V/ms

VZCD = VZCD(TRIG) to VDRV = 90%

Falling VDRV = 10% to

Rising VDRV = 90%

VZCD(ARM)

VZCD(TRIG)

VZCD(HYS)

IZCD

VCL(POS)

VCL(NEG)

tZCD

tSYNC

tstart

1.25

0.6

500

−2

9.8

9.2

−0.9

−1.1

−

−

75

1.4

0.7

700

−

10

10

−0.7

−0.7

100

70

165

1.55

0.83

900

+2

12

12

−0.5

−0.5

170

−

300

V

V

mV

mA

V

V

ns

ns

ms

DRIVE

Drive Resistance

Isource = 100 mA

Isink = 100 mA

ROH − 12 20 W

ROL − 6 13

Rise Time

10% to 90%

trise − 35 80 ns

Fall Time

90% to 10%

tfall − 25 70 ns

Drive Low Voltage

VCC = VCC(on)−200 mV,

Isink = 10 mA

Vout(start)

−

−

0.2 V

Product parametric performance is indicated in the Electrical Characteristics for the listed test conditions, unless otherwise noted. Product

performance may not be indicated by the Electrical Characteristics if operated under different conditions.

6. For coldest temperature, QA sampling at −40°C in production and −55°C specification is Guaranteed by Characterization.

www.onsemi.com

5

5 Page

NCP1608

high frequency switching converter to regulate the input

current harmonics. Active circuits operate at a higher

frequency, which enables them to be physically smaller,

weigh less, and operate more efficiently than a passive

circuit. With proper control of an active PFC stage, almost

any complex load emulates a linear resistance, which

significantly reduces the harmonic current content. Active

PFC circuits are the most popular way to meet harmonic

content requirements because of the aforementioned

benefits. Generally, active PFC circuits consist of inserting

a PFC pre−converter between the rectifier bridge and the

bulk capacitor (Figure 26).

Rectifiers

PFC Pre−Converter

Converter

AC Line

High

+ Frequency

Bypass

Capacitor

NCP1608

+ Bulk

Storage

Capacitor

Load

Figure 26. Active PFC Pre−Converter with the NCP1608

The boost (or step up) converter is the most popular

topology for active power factor correction. With the

proper control, it produces a constant voltage while

consuming a sinusoidal current from the line. For medium

power (< 350 W) applications, CrM is the preferred control

method. CrM occurs at the boundary between

discontinuous conduction mode (DCM) and continuous

conduction mode (CCM). In CrM, the driver on time begins

when the boost inductor current reaches zero. CrM

operation is an ideal choice for medium power PFC boost

stages because it combines the reduced peak currents of

CCM operation with the zero current switching of DCM

operation. The operation and waveforms in a PFC boost

converter are illustrated in Figure 27.

AC Line

Diode Bridge

Vin

+

+

−

Diode Bridge

IL

Vin

+

L

+

Vdrain

AC Line

−

IL

Vdrain

L

+

Vout

The power switch is ON

With the power switch voltage being about zero, the

input voltage is applied across the inductor. The inductor

current linearly increases with a (Vin/L) slope.

Inductor

Current

Vin/L

IL(peak)

The power switch is OFF

The inductor current flows through the diode. The inductor volt-

age is (Vout − Vin) and the inductor current linearly decays with a

(Vout − Vin)/L slope.

(Vout − Vin)/L

Critical Conduction Mode:

Next current cycle starts

when the core is reset.

Vdrain

Vout

Vin

If next cycle does not start

then Vdrain rings towards Vin

Figure 27. Schematic and Waveforms of an Ideal CrM Boost Converter

www.onsemi.com

11

11 Page | ||

| Páginas | Total 24 Páginas | |

| PDF Descargar | [ Datasheet NCP1608BDR2G.PDF ] | |

Hoja de datos destacado

| Número de pieza | Descripción | Fabricantes |

| NCP1608BDR2G | Critical Conduction Mode PFC Controller Utilizing a Transconductance Error Amplifier | ON Semiconductor |

| Número de pieza | Descripción | Fabricantes |

| SLA6805M | High Voltage 3 phase Motor Driver IC. |

Sanken |

| SDC1742 | 12- and 14-Bit Hybrid Synchro / Resolver-to-Digital Converters. |

Analog Devices |

|

DataSheet.es es una pagina web que funciona como un repositorio de manuales o hoja de datos de muchos de los productos más populares, |

| DataSheet.es | 2020 | Privacy Policy | Contacto | Buscar |